| Being a

BMW, of course the engine is probably the best and the

easiest part to work with because the engineering is so superbly done.

It was also the part about this car I worried the least about since it was

not worn out, just neglected for a decade and not driven much. Once we

opened her up, the contents of the engine confirmed our hunches - that it

was in really good shape. On the outside she was mighty greasy though, and

some of that grease had built upon mold that was from sitting in a damp

place for so long. Don't do that with your car - it's really nasty and green

and hard to get off! (Back view prior to transmission removal). These

photos are a look into the engine in ways the shop manual doesn't really

show you. |

|

|

A look at the exhaust side of the block. That rusty port on

the back of the cylinder head is what feeds one side of the heater system.

There is an improved part that came from the E30 4 cylinder models that is

better. Get a look at the greasy mold on the back of the transmission!!! |

|

|

Another view. That hole in the transmission bell housing is

where you shine your timing light and look for the ball bearing on the

flywheel to set perfect time. |

|

|

Ok, a trick here. You've not seen an engine mounted to the

side like this, but this is the way BMW does it. (A BMW AG employee

confirmed it for me who worked there in 70s) It makes sense, you want to put

the flywheel and clutch on without having to take it off the stand.

This side of the block is usually greasy because the exhaust studs come

loose and oil leaks onto the block causing one bad mess on the street. Ask

me how I know! |

|

|

A close up of which engine stud holes I used to mount the

engine with. Thanks to Lars Floden for the use of his brother's engine

stand to get this hunk out of the car and onto the stand. |

|

|

Intake side. This shows the stub manifold for the injectors,

the TII water tube and a bunch of the buried hoses you never see under the

intake manifold. Original TII heads had the passage for the fuel pump of

carb models sealed up, as shown right above the first injector hole to the

left. |

|

|

Ok, after more parts come off, here's a look at the back of

the kugel pump and the hoses that connect to the block it takes advantage

of. |

|

|

After the oil pan comes off, a look at the oil pump chain and

sprocket. |

|

|

The connecting rods and a view of the #3 piston skirt.

|

|

|

The rear main cap and back of the flywheel. |

|

|

The oil pump siphon screen that sits down in the deepest part

of your oil pan. The shiny spot in the middle is where I ran a cloth over

the surface to show that dirty oil film collects here. |

|

|

Another side view of the oil pump and #1 and #2 cylinders. |

|

|

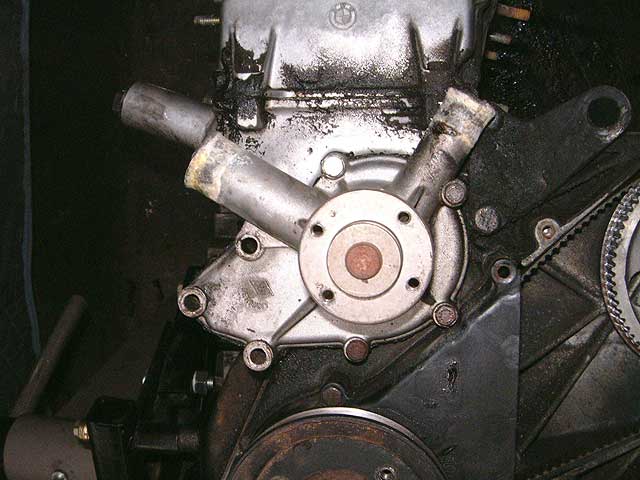

The TII water pump, head on, showing the seven bolts holding

it on. |

|

|

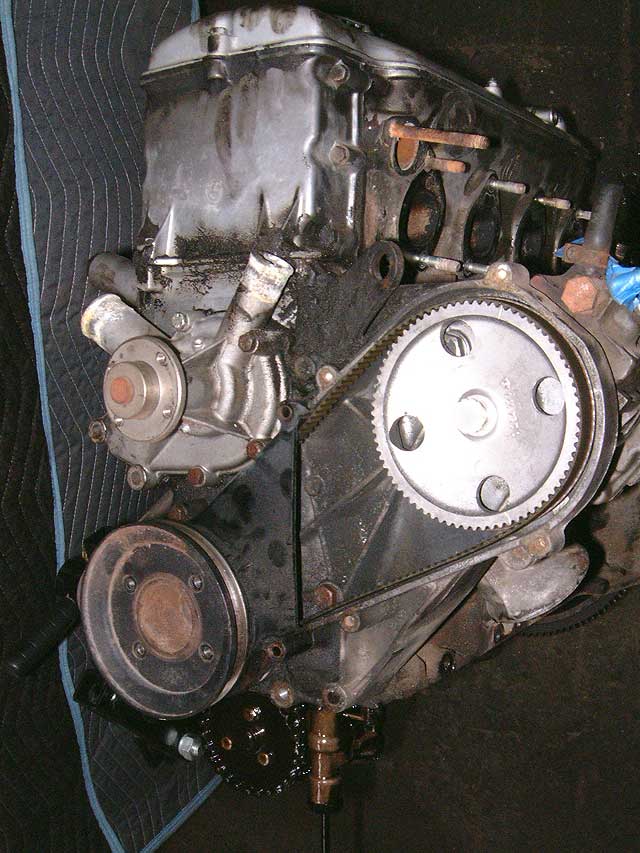

A view of the TII timing cover from the front, with the fuel

injection pump still installed. |

|

|

Ok, we removed all the intake side parts and have a clean

short block. |

|

|

Top side, a look at the head. Pretty clean, but varnish

deposits from sitting or having dirty oil in the block or extended periods

of time. |

|

|

Remove the upper timing cover and the chain is exposed.

|

|

|

Take out the safety tabs on the screws and the timing

sprocket comes right off. |

|

|

After taking the head studs loose with a 19mm socket, the

head comes off. The white powdery stuff is from the water passages in the

block. More evidence of sitting for a long time. The stuff is like a chunky

white powder substance. Bad valve stem seals show the result - oil from

deceleration is burned off - the legendary white puff out the tailpipe on

downshift. |

|

|

Head gasket still on, you can see the O rings used for the

cutting ring style gasket the TII's and TURBOs use. This is important on

very high compression engines. Piano top pistons are the style used in a 74

TII with E12 head. |

|

|

A view of the top of all 4 pistons. In this view, Cylinders 1

and 4 down, 2 and 3 up. |

|

|

A view of the head. The head is in overall good shape, it's

never been opened until this point so this is the factory's handiwork shown.

I'm pleased that I have a good head to leave at the machine shop. |

|

| |

|

Well, this is the first step, getting it apart. More as we

start to put her together in the next few weeks. |

| |

|

Back to Page 1, or

October Update is here -> |

| |